In this series, we will look more closely at the exceptional rare handcrafts that Patek Philippe is preserving and pioneering. There is no other watchmaker in the world that has nurtured and mastered these ancient crafts to the same level as Patek. Today, decorated watches are back in vogue, but Patek Philippe has always worked with master craftspeople and protected their skills, without a break, for over 180 years.

Historically, the demand for decorated Swiss, and in particular Genevan watches, reached its peak in the nineteenth century then declined quite rapidly after the Second World War. Other than Patek Philippe, all the brands abandoned what had become a niche sector of horology, resulting in only a handful of artisans left who still practiced traditional techniques like engraving or enameling. Under the guidance of the Stern family, Patek Philippe continued to employ artisans and produce pieces, even if they had to be put aside until a buyer could be found. Consequently, the most talented artisans still work at Patek Philippe where they are given the artistic freedom to push their skills to ever more extraordinary levels.

Patek was rewarded for its patience and commitment to rare handcrafts and over the past decade there has been a significant up-swing in the demand for highly decorated watches and clocks. Thankfully, as other watch brands re-introduced traditional decorative techniques, training programs that had been closed have re-opened, enabling the few remaining masters to pass their skills on – just in time.

In the past, Patek would produce a few dozen unique watches and clocks each year which demonstrated the use of rare handcrafts at the highest levels, providing the artists with an incomparable canvas on which to practice his or her skills. Coveted by knowledgeable collectors, these pieces were rarely seen, except for a rare glimpse of one or two at the Basel Fair or a special exhibition. In 2011, Patek decided to hold a discreet exhibition in its Salon in Geneva of its current rare handcraft pieces. The exhibition was repeated the following year with no fanfare, but by 2013, the international press took notice, and the world was dazzled by the exceptional pieces crafted in the Patek workshops. Publicly displaying the range of its rare handcraft pieces had a huge impact. “We did it to set the record straight”, says Thierry Stern. “… it was time to remind the public of the role we play in this area. However, the problem was that we had 650 requests for 75 pieces.”

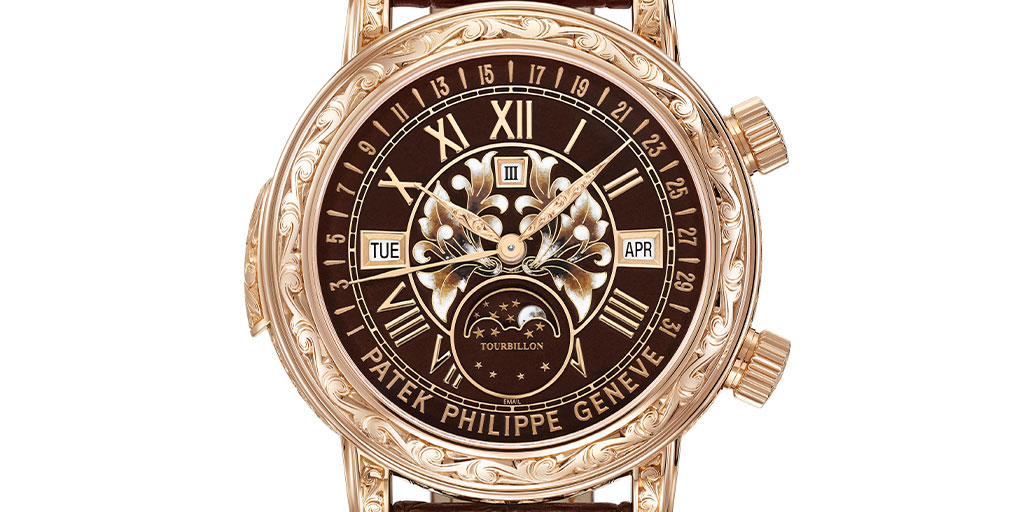

We will start this series with engraving, a decorative art form that is intrinsically tied to the history of Patek Philippe, and is the oldest form of decorative art in watchmaking. An engraved pocket watch or wristwatch is sculptural thanks to the way in which the talented men and women engravers bring metal to life. The fluidity of the cases, the texture, the way it feels, looks and plays with the light – these are all part of the art of engraving.

When Antoine Norbert de Patek first started to sell timepieces, his clientele were wealthy members of the Polish aristocracy – people he either knew personally, or to whom he could be introduced. To satisfy his clients desire for the very finest timepieces, many of the pocket watches were intricately engraved. Clients could also commission designs to be engraved, and as miniature enameling became popular, portraits of loved ones or themselves would be included either on or inside a cover.

The pocket watch above is a perfect example of an early piece commissioned by a Polish client, Mr. Redziewicz in 1847. The intricate, richly engraved covers depict a view of Warsaw on one side and Vilna (today the capital of Lithuania) on the other.

The cuvette of this watch is signed Patek i Spólka, “Patek & Co.” (above), the signature used between 1845 and 1851. Patek hired Adrien Philippe in 1844 as technical director and Philippe was slowly implementing his keyless winding system into the young company’s production. It was not until 1851 that the company is renamed ‘Patek, Philippe & Co’. The cuvette is also engraved with a coat of arms depicting a tied arch and inscriptions: 1848 Norbert Redziewicz, Patek i Spólka W Genewie, Nr. 2789, Wychwyt Kotficzny, Trzy Podnoszenia z Rubinów, Dziesiec Czopów w Rubinach. Cieplochron (Patek & Co. in Geneva. Lever Escapement. Three Ruby Liftings. Ten Pivots in Rubies. Heat Protection).

The cuvette of this watch is signed Patek i Spólka, “Patek & Co.” (above), the signature used between 1845 and 1851. Patek hired Adrien Philippe in 1844 as technical director and Philippe was slowly implementing his keyless winding system into the young company’s production. It was not until 1851 that the company is renamed ‘Patek, Philippe & Co’. The cuvette is also engraved with a coat of arms depicting a tied arch and inscriptions: 1848 Norbert Redziewicz, Patek i Spólka W Genewie, Nr. 2789, Wychwyt Kotficzny, Trzy Podnoszenia z Rubinów, Dziesiec Czopów w Rubinach. Cieplochron (Patek & Co. in Geneva. Lever Escapement. Three Ruby Liftings. Ten Pivots in Rubies. Heat Protection).

This watch is from a pivotal, transitional time in the company’s history, representing Patek’s earliest client base, a special-order accommodation, and the fact that it is wound with a key (before the introduction of Adrien Philippe’s keyless system and his name on the dial). Today, it is exceedingly rare for Patek Philippe to accept a special-order accommodation, but its extensive, annual production of engraved watches provide unique pieces of art for all tastes.

Engraving can be featured on a multitude of surfaces on a watch, from the dial to the movement components or on a case. It’s a time-consuming process – it can take more than a week to engrave a case. Before employing one or more of the three traditional engraving techniques: line engraving, relief or repoussé and champlevé, an artisan will start each new piece with a drawing of the design. The drawing is then transferred to the metal surface in dry point. This becomes the template for the engraver’s tools to follow. Burins, chisels, and other sharp metal blades with wooden handles are among the tools used for engraving, the same tools which have been used for hundreds of years.

The path traced by the burin (the engraver’s slender chisel to make a fine line) requires perfect coordination between the engraver’s hands. One hand pushes the burin onto the metal; the other holds the metal by means of the engraver’s ball, which clamps and rotates the piece into the best position as work progresses. To see the details as they emerge, the artisan uses a binocular microscope — together with absolute concentration. The burin or chisel (for broad furrows) almost becomes a paintbrush. Engraving creates shining, swooping lines and a play of light and shadows on a tiny, resistant metal canvas no more than 2 mm thick.

In addition to artistic flair, the engraver requires infinite dexterity to complete each piece. The basic engraved decorations often center on patterns of interlacing arabesques and spiral scrolls, but Patek’s artists master many other motifs as well.

Inspired by a specific Patek commission or by pure imagination, an endless variety of scenes take shape beneath each burin.

One of the most exciting times for innovative engraving at Patek Philippe was from the late 1950s through the 1960s when Gilbert Albert was head of the creative department. Gilbert Albert completely re-invented the way in which Patek Philippe and other companies looked at watch design. A watch case was no longer round or rectangle, but asymmetrical and triangle. Not even the pocket watch remained unchanged and designs such as ‘Ricochet’ brought this elderly statesman firmly into the Swinging Sixties. Albert combined his love of nature with modern art by using shape and engraving techniques to give his designs an organic and often ‘other-worldly’ look and feel.

Engraving is an important decorative technique to distinguish limited editions, or unique pieces. The first official limited edition watch produced by Patek was the refs. 897 and 898 to commemorate the 50th anniversary of the Federal Shooting Competition in Lucerne, 1979. 100 pocket watches were made for men and 50 pendant watches for ladies. The first example was given to the winner of the Federal Shooting Competition, the second to the Patek Philippe Museum. The remaining pieces were sold by famed Swiss retailer, Gübelin, Geneva.

The watch was designed by master horologist Jorg Sporing in Luzern. The front cover featuring William Tell and his crossbow is designed and engraved by Hans Erni. The back of the case with the pierced apple design was engraved by Eric and Jean-Pierre Monnier.

One of the most important limited edition timepieces, the Star Caliber 2000 is a masterpiece of both horological innovation and classic engraving. With 21 complications and six patents it remains one of the most complicated timepieces ever made. The Star Caliber 2000 was presented in five different sets of four watches, exquisitely displayed in a magnificent ebony box with applied gold engraving (below).

Four sets consisted of pieces in 18K yellow, white and rose gold and platinum. Each of the watch cases in each set had the same engraving, but each set had its own unique design. The original cost of one of these sets was 13.2 million CHF (around 7.5 million USD at the time). The fifth set, made entirely in platinum presented each watch with a different engraved motif. Please see this Collectability interview with Christian Thibert Patek’s then master engraver who engraved each watch case and designed the presentation boxes. Mr. Thibert regards these pieces, especially the four platinum watches and the special architectural display he made for the owner in Qatar, as his personal masterpieces.

Every engraver has his own personality and develops his own recognizable style. In an interview with Collectability, master engraver Christian Thibert explained how the way in which an artist engraves and designs light movement and reflection in each cut is the signature of the artist’s personal touch or style. “This is what I call the life of the piece.” says Thibert, “I can recognize the engraving of someone I have worked with or know. When I was at the École Boulle in Paris, I could recognize which apprentice had engraved a particular piece even if other apprentices had been asked to engrave the same motif.”

Master engravers would sign their names on special engraved pieces. For example, M. Nerlich and H. Erni in the 1970s; E. Kohler in the 1980s; Ch. Thibert until the early 200s and Ch. Blandenier more recently to name a few.

When Patek introduced its dome clocks in the mid-1950s, they were not the elaborately decorated cloisonné enameled pieces they are today. The first examples, made of gilt brass were hand-engraved with geometric designs like the piece above. At the time, these clocks that harnessed the power of the sun were the most cutting-edge technology one could buy for the home. They were also considered a luxury, and with a price tag of $1250 (compared to a ref. 1518 which was around $1500) they were a special addition to few homes.

One of the most spectacular expressions of the use of engraving in horology is undoubtedly the engraving of a skeleton movement. Patek Philippe skeleton watches are the ultimate form of transparency in watchmaking — there is nothing to hide! Every component that can be made from gold is gold. Every square millimeter is cut and engraved by hand. With a traditional Patek Philippe movement, typically only the watchmaker can enjoy the hidden pleasure of hand finished parts, especially in solid-back watches. With a skeleton timepiece, everything is on view. The tradition of skeletonizing Patek Philippe movements goes back to the 1860s when Patek produced a small series of skeleton pocket watches. These pieces were often made for exhibitions and display purposes so that Patek Philippe could showcase their high degree of finish.

It was not until the late 1970s that Patek introduced skeleton pocket watches (ref. 894) into its regular production, and 1980 for the introduction of skeleton wrist watches with the Ellipse ref. 3880. For the definitive guide on Patek Philippe skeleton watches please see this Collectability article.

In 1789, nearly two hundred engravers were registered in Geneva alone, but between 1970 and 1980 their craft had almost disappeared. Today, having only just survived, hand engraving is in demand, and even though the great craftsmen are in short supply, the survival of the next generation of engravers seems assured. One thing we can be assured of is that Patek Philippe will always provide a home for engravers, no matter how trends may change in the future.