This summer, Collectability and Analog:Shift present the largest collection of Patek Philippe electronic clocks ever assembled for public viewing in New York City. The ‘Meeting Point’ exhibition is the most significant collection of its type and redefines our understanding of quartz timekeeping. Valued at over $3 million, the collection consists of over 40 electronic clocks painstakingly accumulated over four decades from 1973 through today.

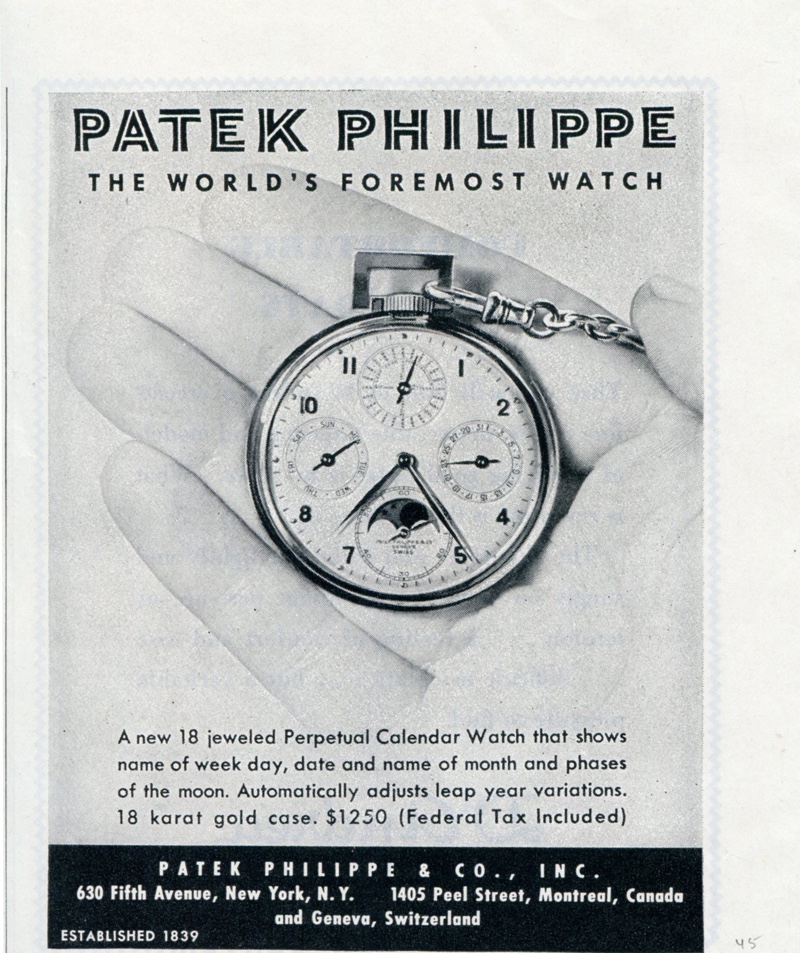

Patek Philippe is universally appreciated as the maker of the world’s finest mechanical watches. What is not so well known is that they were the world’s foremost maker of electronic master clocks and led the technology behind atomic and quartz clock and watch development.

Patek Philippe established its Electronic Timekeeping Division in 1948 with the primary goal of developing the most accurate timekeeping clocks and watches on the market. It was during the 1950s, ‘60s, ‘70s and ‘80s that the Swiss company perfected this remarkable technology, and their master clock systems were regarded as the most cutting edge and precise systems on the market.

These incredible systems were crafted on a commission-only basis, mostly for commercial use, and provided the time through a master clock system that in turn operated additional subsidiary clocks. An array of businesses and services, including airports, railways, hospitals, radio stations, nuclear power plants, parliaments, military, NASA, the United Nations, the Vatican and even other watch brands such as Rolex used Patek Philippe’s timing systems to ensure that the exact time was uniformly displayed throughout a building or complex. Today, the relatively few unique electronic timekeeping systems created by Patek Philippe are extremely rare and seldom appear on the market.

As we look deeper into Patek Philippe’s extraordinary development of electronic clocks, we learn that Patek Philippe led the world in this essential technology. These master electronic clocks were in effect the Tesla cars of their era in terms of their state-of-the-art technological advancements. No other company could compete with Patek Philippe’s engineering, and these clocks are a critical part of the history of watchmaking, and they also re-write our understanding of the Quartz Revolution. It’s nearest ‘competitor’ at the time was Seiko, a company equally invested in quartz miniaturization. In many ways, the race to perfect the use of quartz in wristwatch production was really between these two brands.

The history of the watch industry as it moved from mechanical to quartz is often a little misunderstood. Referred to as the “Quartz Crisis” it is generally accepted that the mechanical watch industry suffered during this transition, but this is just part of the story. It cannot be overstated how Patek Philippe embraced this new technology. Even though there was a potential threat to its industry, Patek Philippe was able to pivot and translate its manufacturing prowess into this new technology. It was the first in the watch industry to really embrace atomic, quartz, solar, and electronic technology. These time keeping machines helped Patek Philippe weather a difficult time in the history of watchmaking.

A brief history of (Patek Philippe electronic) time

When then President Henri Stern started the Electronics Division of Patek Philippe in 1948 he recognized that the future of quartz technology would have a huge impact on the watch industry. Keeping the control of this important new department within the family, its first director was Henri Stern’s half-brother Georges Delessert. Rather than pretend that quartz technology could never replace mechanical watches like many Swiss watch manufacturers did, Patek Philippe threw itself into mastering quartz timekeeping and with it, created many of the world’s firsts in a form of timekeeping that we now take for granted.

In 1952, Patek Philippe presented the world’s first electronic clock without contacts or moving parts. Thanks to the introduction of the transistor, this invention quickly led to the first fully electronic timekeeper in 1956 — measuring four feet by two feet, it was certainly not small, but a serious piece of technology and a powerful statement of intent. A mere two years later in 1958, Henri Stern proudly announced, “the world’s first miniaturized quartz chronometer.” Patek Philippe had proved that it could master the skills necessary to enter this new realm of hyper-accurate timekeeping. The US government also thought that this was an achievement worthy of the atomic age and awarded the company its prestigious Miniaturization Award, the first time it was presented to a non-American product. The clock stood less than five inches high and was powered by solar energy. Patek Philippe had now given this new way of telling time the dignity and recognition it deserved.

In 1959, Patek Philippe produced the first quartz-powered marine chronometer – a fully transistorized clock measuring approximately 1,000 cm3. This prototype was the smallest quartz clock in the world at that time. The case was made of plexiglass. The frequency of the 10k hertz quartz was reduced to 162/3 hertz with transistors. This current was amplified and drove a synchronous micro-motor of 30 milliwatts. The small second hand, located at “6”, did not jump, but “swept”, much like the second indicator of the later Beta 21 wristwatch. As the oscillation frequency of a quartz crystal depends on the outside temperature, the clock was fitted with thermal compensation. It passed the test for marine chronometers at the observatory in Geneva with an average deviation in daily operation of ±0.01 5/d.

From then on, Patek Philippe continued to rapidly develop its quartz technology and electronic timekeeping. In 1960, the company officially unveiled its first, fully transistorized miniature quartz clock called the Chronotome. The term ‘Chronotome’ referred to an electronic chronometer or Chronoquartz system that operated from small, built-in batteries. By 1962, the Patek Philippe Chronoquartz systems claimed another two world firsts: the first quartz chronometer to be produced in series, and the first timekeeper of the kind to have its accuracy certified by the Swiss observatories. So accurate was this new timekeeper that the Geneva and Neuchâtel Observatories had to change their recording measurements from one hundredth of a second to one thousandth of a second. Because Chronotome clocks were relatively small and could be run by battery power, they became popular with Navies around the world. Known as marine chronometers, special covers were made to protect against magnetic and gravity fields, moisture and dust, atmospheric pressure variations and temperature fluctuations. Clients such as the Italian and French Navies equipped many of their ships with Patek Philippe Chronotome and Chronoquartz clocks. The advantages offered by a quartz marine chronometer in commercial marine applications were first made reality around 1968. They were more accurate than comparable mechanical clocks, less sensitive, and required no additional attention during operation in addition to less maintenance.

An early Chronotome clocks was given to President Kennedy by Willy Brandt, the mayor of Berlin the day after his iconic “Ich bin ein Berliner!” speech in 1963. The Chonotome clock was designed as a complement to the ”red telephone” and represented an instrument of peace showing the time in Moscow, Washington D.C., and Berlin on three clock faces.

Even before the Chronotome historic clock was given to the leader of the free world, Patek Philippe was focusing on even bigger projects: providing accurate time to industry, transport networks and even countries. In 1961, the first master clock with quartz oscillator and solid-state circuits was introduced. Patek Philippe master clocks and subsidiary units started appearing throughout Europe in airports, railway systems, hospitals and broadcast networks. By 1967, the hundreds of subsidiary clocks throughout the Vatican City were kept on time by a Patek Philippe master clock. This new generation of Patek’s master clocks were now 100 times more accurate thanks to use of the first radio receiver that automatically synchronized clocks via the HBG time signal of the Prangins transmitter near Geneva. From now on, master clocks had an accuracy of one thousandth of a second per day.

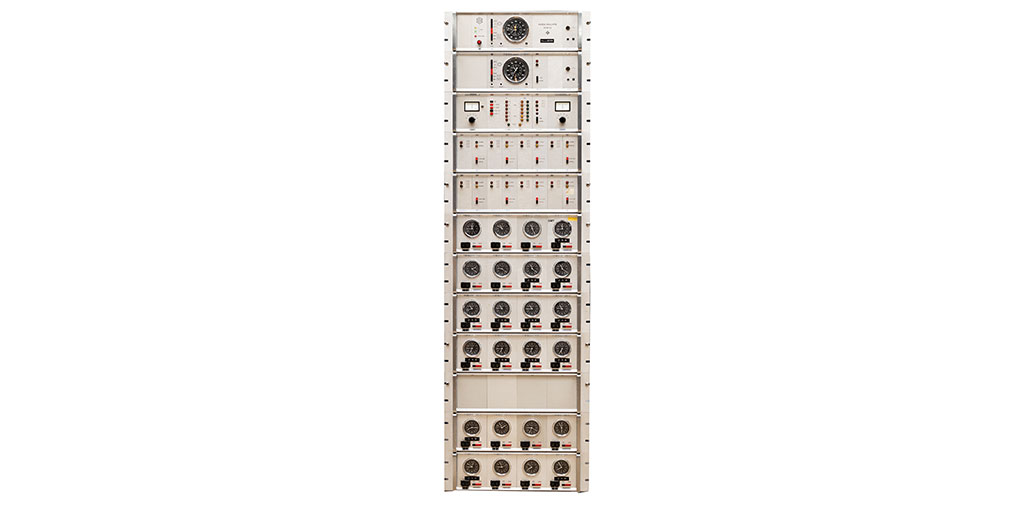

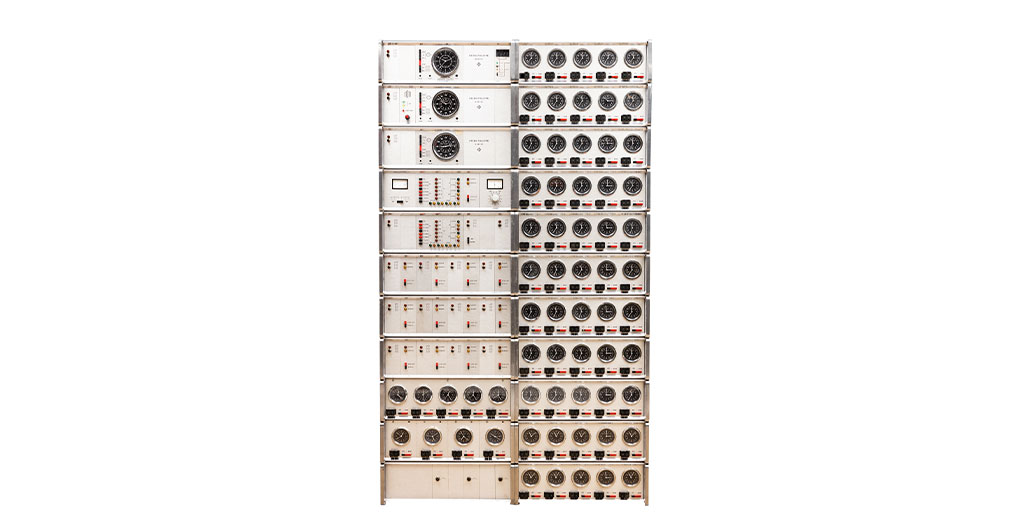

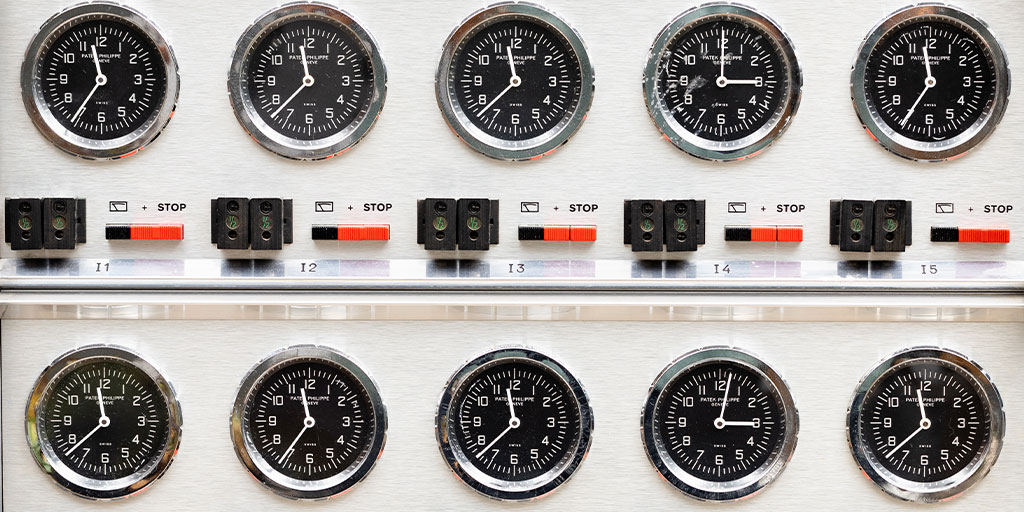

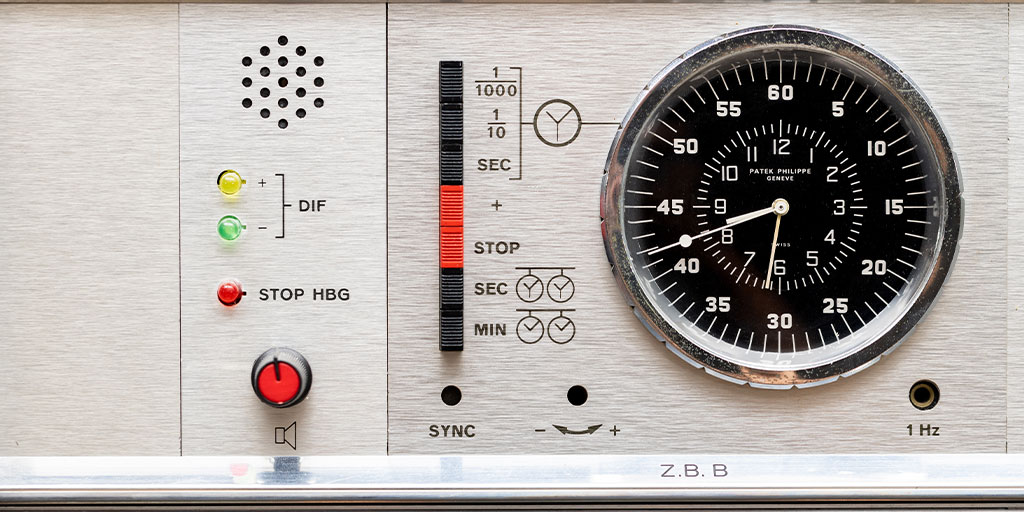

Patek Philippe officially introduced its first Chronoquartz master clock system at the Basel Fair in 1964. These clocks were made for institutions and organizations were the accuracy and reliability of timekeeping functions was of absolute importance. This system, known as the T3, is composed of a central chronometer and a reserve chronometer continuously controlled by a third unit with its own timing unit (three master clocks). Therefore, if one clock becomes difunctional, there are still two others as back-up. If two clocks indicate the same time, the system is presumed accurate. The Chronoquartz T2 (two independent quartz clocks) followed in 1965. These systems formed the backbone of Patek Philippe’s electronic master clock systems and were used until the introduction of micro-processors in the early 1990s.

In 1969, the “MI” production line, an acronym for “modular integrated”, debuted, replacing Chronoquartz production. The progress was initially limited to the external design of the time center and the rearrangement of the electronics taken over one to one from the Chronoquartz series. Their individual parts were redesigned into groups or modules and then installed as racks. Although Patek Philippe in 1969 was familiar with the 19-inch racks that were later commonly used – because there is a Chronotome from 1963 in a 19-inch rack – Patek Philippe engineers use their own unit of measure for the MI series. Different functions were assigned to the individual racks, they were placed one on top of the other and firmly connected to one another. A tower created in this way formed a time service facility. The number of racks varied from plant to plant. However, there were never more than 11 racks in a tower. The largest time service system ever built had 22 racks, which stood next to each other in two towers of 11 racks each. The 22-rack system can be seen in “The Swiss Parliament Clock” in this collection.

Another area of electronic timing systems that Patek Philippe excelled in was professional telephone surveillance. The Z4 system was a tape-documentation system (TDA) developed in 1977 for evidential recording and rapid access through the encoding of time and date on magnetic tapes. During the early 1980s, Italy fitted many of its warships with such a system.

By the beginning of the 1990s, the once state-of-the-art technology behind Patek Philippe electronic master clocks began to become obsolete and Patek replaced the systems with another first: the Telequartz. This microprocessor-controlled radio clock was 60 times smaller than tower systems. It still read the DCF-77 radio signal and displayed the time fully automatically via LCD while controlling countless subsidiary clocks without issue.

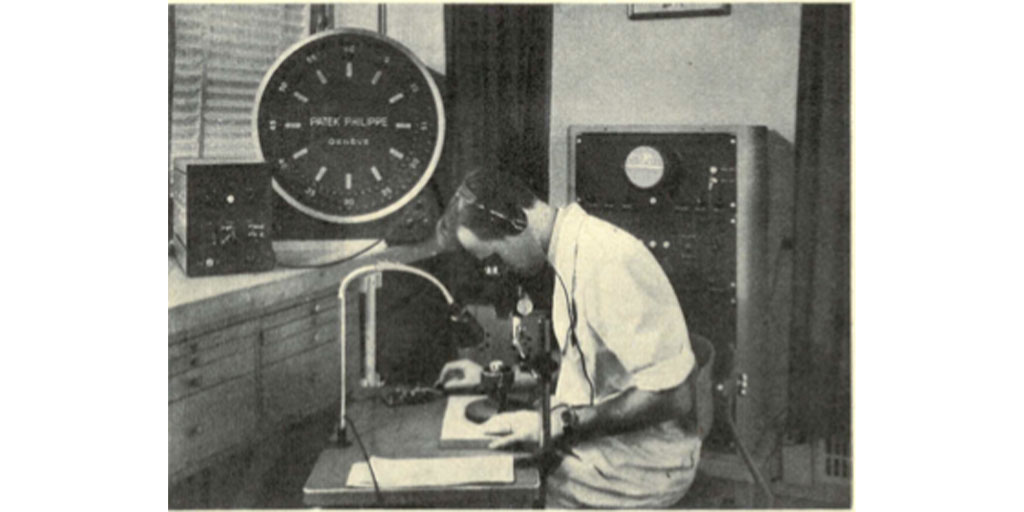

During the 1960s, 1970s and early 80s, Patek Philippe made master timing clocks for Rolex and other leading watch makers such as IWC and Zodiac. Rolex used the Patek Philippe timing systems to operate small, synchronized clocks that were on the workbenches of watchmakers. Rolex watchmakers used these clocks to test the timing accuracy of the watches they were making. All clocks were housed in the company’s iconic green casing.

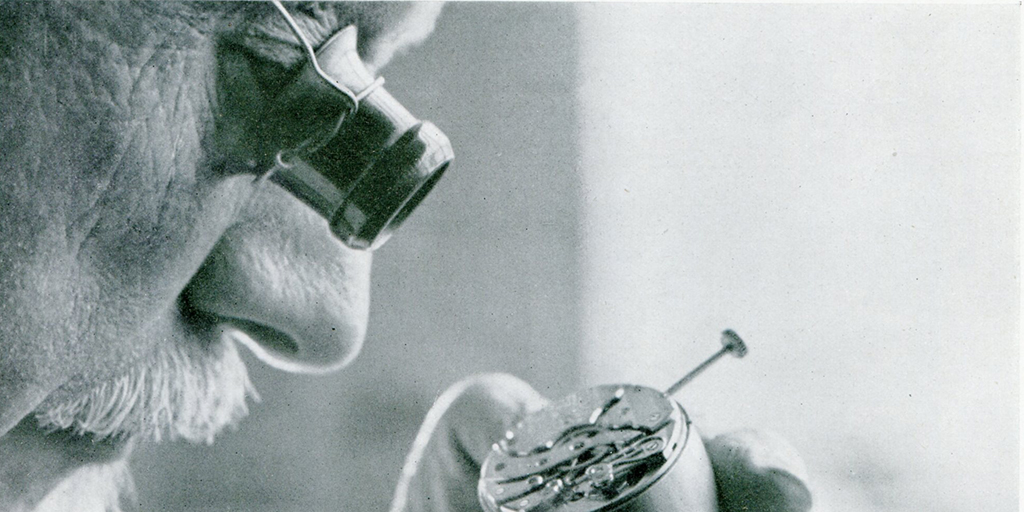

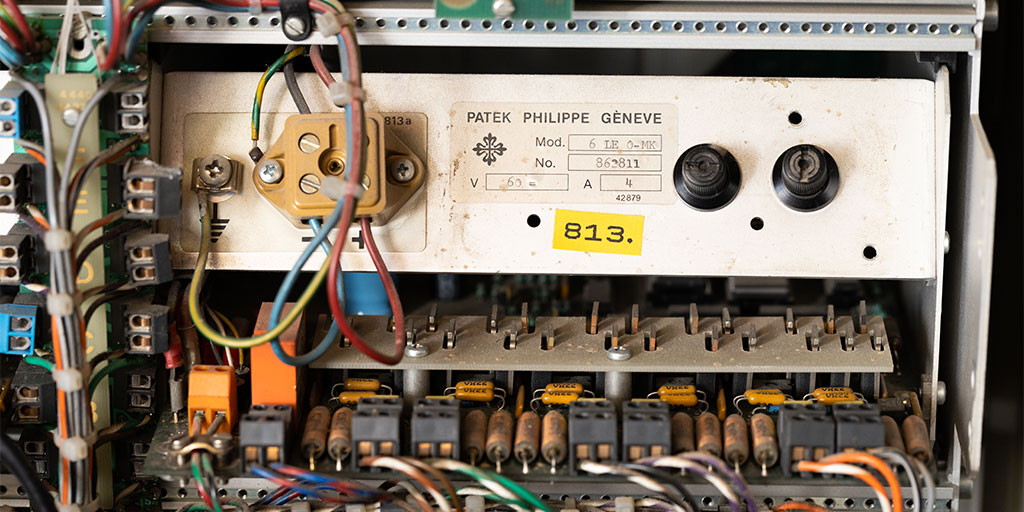

Patek Philippe put the same attention to detail into making each of the many thousands of components that went into a master clock as they did with their mechanical watches. Even the circuit boards were produced to Patek Philippe’s exacting standards and plated in silver, as opposed to copper. The outline for the circuit boards were drawn entirely by hand and have tolerated many soldering and de-soldering from engineers during maintenance over the years. These circuit boards still work today and will be around for generations, even if their technology is now obsolete. Thanks to the exceptional standard of engineering, the accuracy of these clocks is comparable to a quartz timepiece today, something truly amazing for its time. During the 1960s achieving the same kind of timing accuracy without an atomic clock was extremely difficult. The components in an electronic clock are susceptible to many variables such as heat, cold, humidity variations and it is extremely difficult to compensate for these in analog electronics. However, Patek Philippe thought of and adjusted for every single scenario that could affect these clocks.

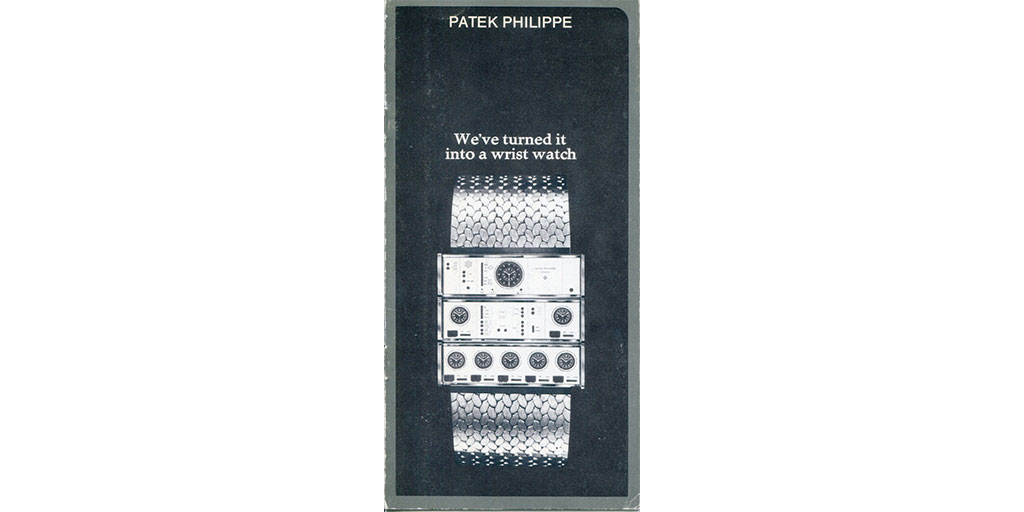

To harness the power of quartz in master clocks, frequency dividers are complex electronic circuits comprising many semiconductors such as transistors, diodes etc. With the invention of integrated circuits in the 1960s, it became possible to miniaturize these components into a tiny square wafer whose sides measure less than 1/10 th of an inch. This in turn made possible the concept of a quartz wristwatch and in 1969 Patek Philippe launched one of the world’s first quartz wristwatches, the Beta 21.

What makes an electronic clock tick?

One of the most stable phenomena known to science is the vibration of an electrically stimulated quartz crystal. Because stability and accuracy are one of the same, it was not long before quartz crystal found its way into watchmaking. A quartz crystal oscillates at 8,192 times per second. This piezoelectric quality was discovered by Pierre and Jacques Curie in 1880. When harnessed by a timekeeper, the ultrahigh frequency of 32,000 hertz (as opposed to 2.5 hertz or 18,000 vibrations per hour of Patek Philippe’s first automatic caliber 12”’600 AT) made it a technology that Patek Philippe could not ignore.

Patek Philippe refers to the system that drives a master clock as a chronometer. A quartz or electronic chronometer is composed of an oscillator (the mechanical equivalent to a balance spring or pendulum) controlled by a quartz crystal and several dividers that transform the original oscillation to a reduced frequency, subsequently driving the hands of a secondary movement. A quartz crystal can oscillate at an extremely high frequency if there is no great variation in temperature. The quartz is therefore mounted and protected from outside temperatures. The division of frequency is obtained by a chain of bi-stable elements. The resulting impulse obtained at an interval rate of one second is used to drive a chronometer by impulse. The principle of driving subsidiary clocks is to amplify the one second impulse and the one minute impulse obtained with further dividers. The distribution of other time impulses is simply obtained by a variation of dividers.

Inside each Patek Philippe master clock, there is a vacuum tube that oscillates at 10,000 hertz, a frequency divider circuit then divides the 10,000 hertz by 10 repeatedly until it gets down to one hertz, which is one pulse per second – the tick tock of the clock. They work through discrete transistors, as opposed to integrated circuits. The source of accuracy and reliability in any electronic time system is the master clock. The most practical source of extreme accuracy is the vibration of the quartz crystal. Under controlled temperature the master clock has an accuracy of a second per day, meaning, the clock can either gain or lose one second in three years.

The circuit boards that run each electronic clock were difficult to design and needed a lot of precision compared with digital circuits today. The engineers at Patek Philippe would hand draw each circuit on a single board, wire circuits would then be soldered onto the board following the line drawn by the engineer. This was an incredibly time intensive process which is one of the reasons the clocks would take a minimum of 18 months to complete. The electronic circuit boards would translate the information into electric pulses of varying amplitude.

These master electronic clocks are also known as “redundant timekeeping service systems” which ensure a synchronized time display of all subsidiary clocks. Time service systems are “redundant” if the components installed in them are multiple, so that the failure of individual parts of the system does not affect the functionality of the entire system. In a redundant time service system, there are replacement components that take on the task of a part that has failed due to a defect. The system performs its service without any interruption even if a problem should occur in one part of the system. Due to the hot-plugging system used from 1969, each of the modules/racks can be removed and installed while the rest of the system is running. The redundant time service system ensures the highest level of operational security. If for example, power fails, all the electronic clock systems included back-up batteries that would maintain clock accuracy until power was restored.

Radio Transmitters and Keeping Perfect Time

Today we can look at our phones and thanks to GPS know exactly what the correct time is. However, until Patek Philippe developed a system for radio synchronization in 1966, the only way to know the precise time was to wait for an announcement from a radio station. Broadcasting accurate time via radio waves is as old as radio broadcasting itself. In Switzerland, for example, the astronomical Observatory of the canton of Neuchâtel, which was founded in 1858, determined the legal Swiss time by evaluating the meridian transit of bright stars and broadcast the time via telegraph wires. From 1928, the time was broadcast on Radio Bern; from 1931, through the Swiss medium wave broadcasters Beromünster and Sottens, and from 1933 via Monte Ceneri once a day at 12:30. If you missed the signal, you had to wait for the next transmission the following day to check the time accurately.

The systems developed by Patek Philippe could directly connect its master clocks with the radio signal and therefore provide constant, accurate time. Patek Philippe clocks first connected to the Swiss HBG time-signal transmitter on Lake Geneva in Prangins via the RHAP system for which Patek received a patent in 1967. HBG was the stations call sign in accordance with the regulations of the International Telecommunication Union (ITU). The first two letters, “HB”, indicate that the transmitter is in Switzerland (country prefix); the “G” indicates its proximity to Geneva. The ground wave had a range of 500km, so reception was reliable throughout Switzerland. Beyond a radius of 1000 km and up to 2500 km signals were transmitted by airwaves.

The HBG long wave data transmitter was unrivaled in Western Europe from 1966 – 1973 until the commissioning of the DCF-77 time signal transmitter in Mainflingen near Frankfurt, which was geographically better placed in Central Europe and eventually made the HBG signal obsolete. Patek Philippe’s electronic clocks started to connect to the DCF-77 time signal from the mid-70s until GPS made radio signals obsolete. By the early 1990s, electronic master clocks were no longer necessary to keep accurate time. Many of the clocks in this collection have been updated to receive a GPS signal.

By the early 1990s, the electronic master clock eventually became redundant due to the rapid development of micro-electrical engineering, especially inexpensive radio-controlled clocks. Large organizations and institutions no longer needed to incur the huge expense of purchasing and maintaining a master clock system. Cheap, radio-controlled clocks could be put in each room of a building and forgotten about until a battery needed replacing. The technology that we have today in our smart phones can be traced back to Patek Philippe’s fearless entry into the then unknown world of electronic and quartz timekeeping. Patek Philippe can be appreciated for its aesthetic beauty, it can be respected for its accuracy, but at its core it’s an innovator and this was particularly true in the mid to late 20th century when Patek was at the forefront of timekeeping technology.

If you would like to visit this exhibition during July and August please email: [email protected]