“In 2005, we decided to create a new concept of advanced research. The idea behind this concept was to show the world all the watchmaking knowledge and mastery of Patek Philippe.”

Thierry Stern, President.

There is nothing simple about Patek Philippe’s Advanced Research as every new revolutionary innovation that the company creates will change the way tomorrow’s watches are designed and crafted. Yet the philosophy behind every Advanced Research innovation is simple: it must “offer the user genuine added value in terms of quality, precision, and dependability in the long run” to quote the Patek Philippe website.

In this article, we will list the Advanced Research innovations to date and explain how they work – as simply as possible! – and why they matter. Launched in 2005, Patek Philippe Advanced Research pioneered the use of Silinvar®, a derivative of silicon which has extremely useful applications for watchmaking. The first silicon-derived innovation was an escape wheel in Silinvar® (2005), followed by the Spiromax® balance spring (2006), the Pulsomax® escapement (2008), the Oscillomax® ensemble (2011), and a further optimized version of the Spiromax® balance spring (2017) and a sound amplifying system for minute repeaters (2021). Each of these technology advancements was accompanied by the launch of a wristwatch in limited editions that incorporated the innovative components. Today, the Spiromax® balance wheel, which is made in-house, has been incorporated into most Patek Philippe movement families, especially in calibers 300 (Grandmaster Chime), 301 301 (Grande Sonnerie), R 27 (except the R TO 27), 240, 28-520, 324, 26-330, 31-260, 25-21, 215 and 30-255.

2005: Silinvar®

Before we look at each of the Patek Philippe Advanced Research innovations, it’s helpful to understand more about Silinvar® itself and why it is such an important material for horology. Silinvar® is a patented material based on monocrystalline silicon. It was developed in collaboration with Rolex, the Swatch Group, and CSEM (Swiss Center for Electronics and Microtechnology) in Neuchâtel. Thanks to a patented oxidation process that causes molecular changes in the outmost layers, it has temperature-compensating characteristics. In the temperature range from -10°C to +60°C, components made of Silinvar® are highly stable – or invariable as suggested by its name (Silinvar® = silicon + invariable).

In addition, Silinvar® has the following properties making it one of the most important advances in horological material:

- It is very lightweight with only a third of the mass of steel. This means that Silinvar® watch components need less energy to function and react less sensitively to the earth’s gravitation.

- Because it is twice as hard as steel it is more resistant to wear.

- Silinvar® cannot be magnetized and therefore not affected by magnetic fields.

- Silinvar® is resistant to corrosion.

- In microstructures, Silinvar® is very flexible but returns to its original shape. Because of this, it is also very shock-resistant and stable.

- Silinvar® components are manufactured with the DRIE process. Deep Reactive Ion Etching produces components of consistently identical shape and quality. Approximately 250 escape wheels can be obtained from the surface of a 100 mm wafer of Silinvar®, which are ready for use except for a final surface cleaning. In other words, they do not require any time-consuming finishing operations such as balancing, chamfering, or polishing.

- Thanks to the DRIE process and the know-how accrued in this domain, Silinvar® components can be manufactured with tolerances of less than 1/1000 mm.

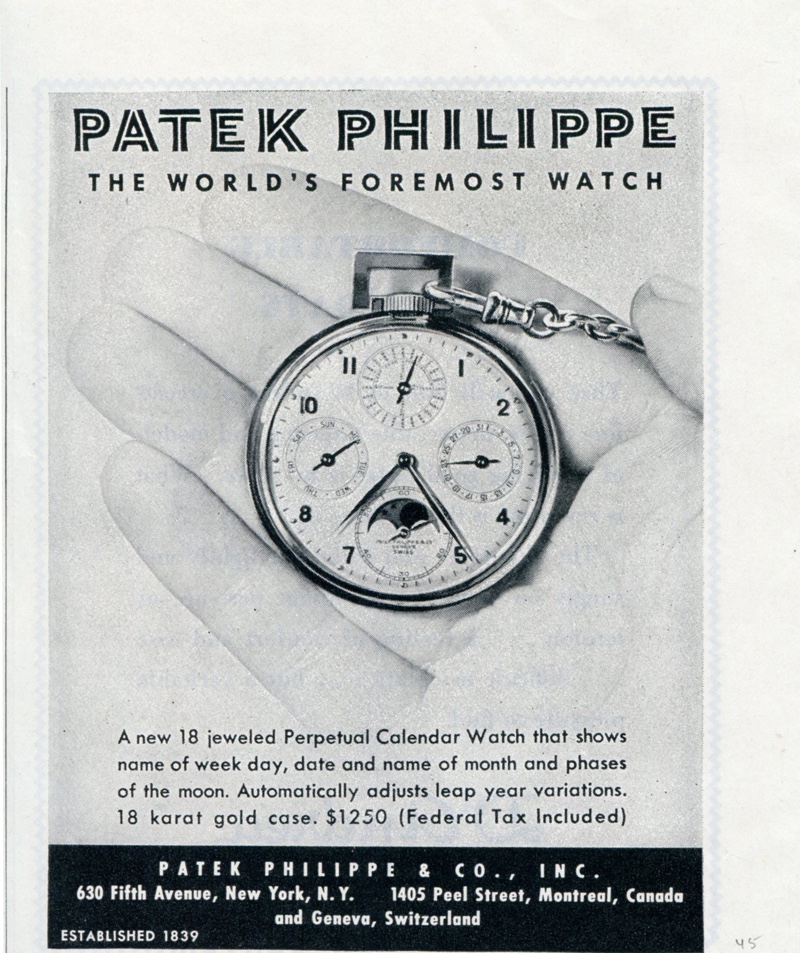

2005: Escape wheel made of Silinvar™

First released in the ref. 5250 Annual Calendar, limited edition of 100

The escape wheel is a vital component in a watch movement because it controls the release of energy from the mainspring that is critical to the accuracy and precision of the watch. The escape wheel translates the back-and-forth motion of the balance wheel into a continuous rotary movement that advances the hands and tells us the time. In a traditional Swiss lever escapement, 65% of the winding energy is absorbed by the escape mechanism.

For decades, Swiss watchmakers have been trying to improve this energy balance. Patek Philippe succeeded in finding a solution with the new Silinvar® escape wheel. Silicon has many features that enables mechanical timepieces to tick more accurately. Because it is three times lighter than a traditional steel escape wheel, it requires considerably less energy to stop and restart. Thanks to the special machining technologies — a layer of silicon oxide is added to the silicon – the need for lubrication is eliminated at the points where it contacts the miniscule pallet stones of the lever. Finally, the use of silicon enables the escape wheel to remain perfectly concentric. The Silinvar® escape wheel is bluish purple in color and can easily be identified through the sapphire crystal back of the movements it is featured in.

2006: Spiromax® balance spring made of Silinvar®

First released in ref. 5350 Annual Calendar, limited edition of 300

To understand how revolutionary the Spiromax® balance wheel is to watchmaking, we need to take a quick look at the history of the balance wheel. Christiaan Huygens is credited with the invention of the balance wheel with a spiral spring in 1675. Since then, watchmakers have worked tirelessly to improve the regularity of its oscillation to come as close to isochronism as possible. Isochronism is derived from Greek roots (iso and chronos) and means “in the same time”. An isochronal oscillator, whether a balance and balance spring, a pendulum, or a quartz crystal in a quartz watch, is essential – without one there is no timekeeping. The factors that defeat isochronism are the asymmetric ‘breathing’ or expansion and contraction of the spring, magnetic fields, the imbalance of the spring, and temperatures changes that effect elasticity. In 1795, the invention of the over-coiled Breguet spring with its outer spring bent slightly upward and inward, eliminated the problem of asymmetric breathing. A hundred years later, Charles Edouard Guillaume created an iron-nickel alloy he called Invar, as in invariable. It automatically compensates for temperature changes and has been the preferred material for balance springs. However, the engineers at Patek Philippe’s technology and material research department felt that there was still room for improvement.

The Spiromax® balance spring made of Silinvar™ offered a new paradigm in timing. Because Silinvar™ is two-thirds lighter than Invar, antimagnetic, corrosion resistant and temperature-compensating, it retains its intrinsic, constant elasticity within a broad temperature range. This material combined with a new balance spring design developed entirely in-house by Patek Philippe and protected by three patents, is just as revolutionary. Even a Silinvar™ spring would naturally expand and contract asymmetrically relative to its center of gravity. The company’s engineers found a brilliant solution by creating a thicker region close to the outer end of the spring. Known as the “Patek Philippe terminal curve” it forces the spring to oscillate concentrically without requiring an over coil. This makes the Spiromax® spring three times thinner than an Invar Breguet spring which makes it perfect for the construction of precise, ultra-thin mechanical movements.

The oscillating behavior of a spring is also influenced by its inner and outer attachment points, so Patek Philippe took another new design approach to address this. In conventional Invar springs, the ends are clamped or soldered. This causes mechanical or thermal changes to the molecular structure of the alloy and requires painstaking adjustment by watchmakers to offset these changes. However, the Spiromax® spring features an integral self-clamping collet in its center and is simply slipped onto the balance staff. At its outer end, the spring has a T-shaped node that clips into a recess in the stud enabling the spring to be mounted in seconds, without any adjustments. Watchmakers love this!

2008: Pulsomax® escapement in Silinvar®

First released in the ref. 5450 Annual Calendar, limited edition of 300

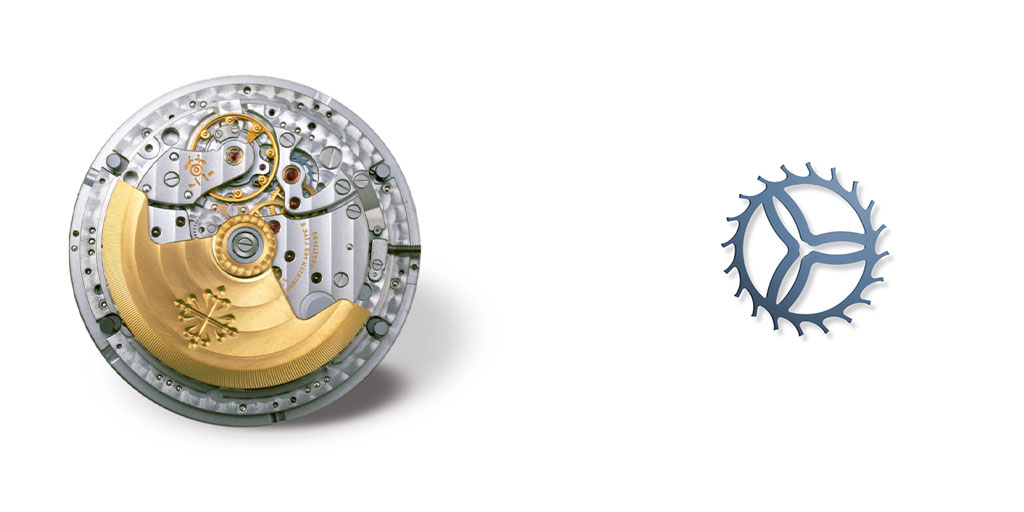

The Pulsomax® escapement is the first escapement made entirely in-house by Patek Philippe. The Pulsomax® combines a new Silinvar® pallet fork with the escape wheel introduced in 2005, and the Spiromax® hairspring introduced back in 2006. This new Silinvar® framework no longer requires a ruby pallet fork to engage the escape wheel. Not only does this reduce the need to manufacture ruby pallet forks, but there is also no longer a need for grinding, enameling (gluing), or complex adjustment of the ruby pallets.

Furthermore, by significantly enlarging the two (integrated) pallet forks, the number of teeth on the escape wheel could be reduced from 20 to 16. This reduces the contact time of the pallet forks on the escape wheel, which in turn saves energy. The new Pulsomax® escapement increases energy efficiency by 15% which in turn increases the power reserve from 45 hours to 60 hours – a welcome addition of power for any mechanical watch owner.

2011: Oscillomax® ensemble = Pulsomax® escapement with GyromaxSi balance and Spiromax® balance spring

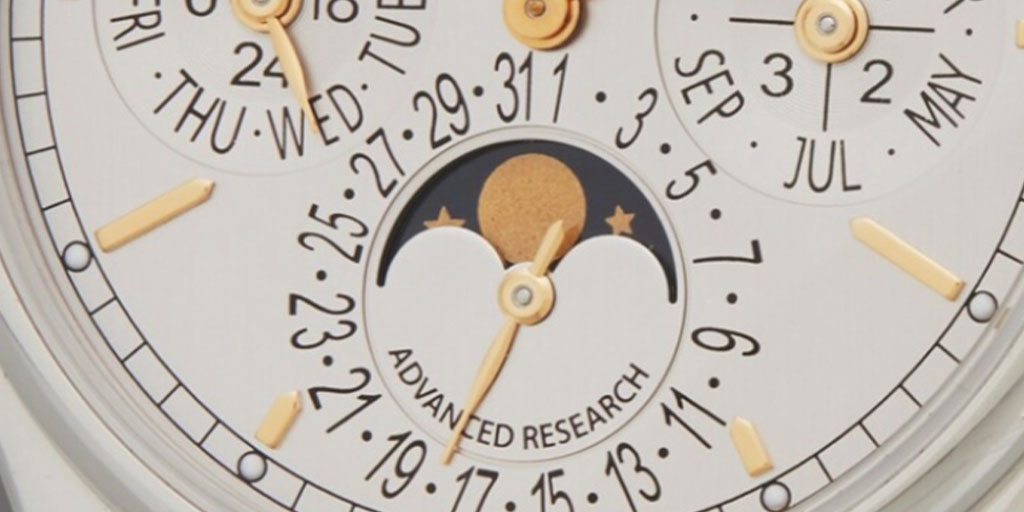

First released in the ref. 5550 perpetual calendar limited edition of 300

The Oscillomax® ensemble at last integrated Advanced Research technology into the legendary perpetual calendar movement rather than just Annual Calendar movements. The caliber 324 S IRM QA LU in the ref. 5550 became the modified caliber 240 Q Si with Oscillomax assembly. For this new caliber alone, Patek applied for a staggering 17 patents. The most significant innovation of the Oscillomax® ensemble was the modification of the Gyromax balance for the first time in 60 years. The GyromaxSi balance is hourglass-shaped, consisting of Silinvar® and 24-carat gold. Engineers found that when a traditionally shaped Gyromax ring balance oscillates, 60% of the energy is lost due to air resistance. As a result, they adjusted the aerodynamics of the balance rim. To achieve the best possible moment of inertia, the balance should be as light as possible in the center and heavier towards the outside. Therefore, the outside of the GyromaxSi balance was weighted with two 24-carat gold masses. For fine adjustment, there are four slotted regulating discs on the periphery next to the two gold masses. The energy gain compared to a conventional Gyromax ring balance is more than 20%, thus the power reserve could be increased from 48 to 70 hours. Another impressive efficiency.

2017: Improved Spiromax® balance spring and compliant mechanism for correcting time zones

First released in the ref. 5650 Aquanaut Travel Time, limited edition of 500

To improve the Spiromax® balance wheel, an additional end curve on the inside of the spring was incorporated. This seemingly simple modification had a significant impact on rate accuracy by counteracting the influence of gravity. Now with both an outer and inner ‘Patek end curve’ on the hairspring, the average rate can be regulated from -2 to +1 seconds per day – the same tolerance range as for a tourbillon! (Just FYI. For certified COSC chronometers the tolerance is -4 to +6 seconds a day).

The second innovation is a time zone corrector with an elastic solid joint. It replaces several springs and levers and consists instead of four intersecting leaf springs: two for each corrector pusher. The new corrector consists of only 12 instead of 37 individual parts, has a flatter design of 1.24 mm compared to the usual 1.45 mm (this reduces friction and wear as well as power consumption) and does not need to be lubricated. To show off this ingenious innovation, for the first time on a Patek Philippe watch, part of the dial was removed so that the new solid-state joint can be seen through the open aperture.

2021: the Fortissimo “ff” module

First released in the ref. 5750P minute repeater, limited edition of 15

In 2021, the engineers in the Advanced Research department took on one of the challenging of all complications: the chime of a minute repeater and developed a totally new, all-mechanical sound amplifying system. Both Philippe and Thierry Stern have made the sound quality of a minute repeater a top priority and the fortissimo “ff” module achieved a new level of sound clarity never heard in the confines of a wristwatch. For the first time since its introduction in 1989, the minute repeater R 27 PS caliber was revised. The fortissimo “ff” amplifier system was installed on the bridge side of the new model. It consists of a sound lever and oscillating plates made of sapphire crystal. The sound lever is attached to the hammers and reaches into the center, where it is supported by the sapphire crystal case back. In a traditional minute repeater, hammers strike a sound gong that spirals around the movement. However, the floating sound lever absorbs the vibrations before they can spread through the case. The sound then reaches the sapphire crystal plate where the actual amplification takes place. Like the funnel of a gramophone, the plate amplifies the vibrations. The sound then escapes exclusively through four openings in a titanium hoop at 12, 3, 6 and 9 o’clock. With this system, the chimes can be heard up to an extraordinary 60 meters away. A traditional repeater is only audible up to 10 meters. Since the amplifier system is completely decoupled from the movement, the case material has no influence on the sound quality. Hence why the ref. 5750 was made in platinum, traditionally the most challenging metal to produce a clear, sonorous chime. Now Patek Philippe could prove the brilliance of its new chiming mechanism – it sounds great even in a platinum case.

Patek Philippe has been pushing the boundaries of watchmaking since Adrien Philippe invented the keyless winding system in 1845. It is on a constant, unyielding quest to make the finest watches and this means constantly being ahead of anyone else. The extraordinary number of patents that Patek Philippe secures for its innovations means that the technologies are difficult to copy. By the time other manufacturers find a way to mimic innovations, Patek Philippe will no doubt be way ahead with a new improvement. At Collectability, we are often asked “Why Patek Philippe?”, the Advanced Research department is one very good reason.

October 2024